APPLICATIONS

As a full-service custom FANUC robotics integrator, we are committed to providing you with the best automation solutions tailored to your unique needs. Our expertise spans various industries, including agriculture, automotive, recreational, and general industry. We specialize in applications designed for machine shops, assembly, and material handling systems, ensuring optimized performance and efficiency. Partner with us to elevate your operations with cutting-edge robotic technology!

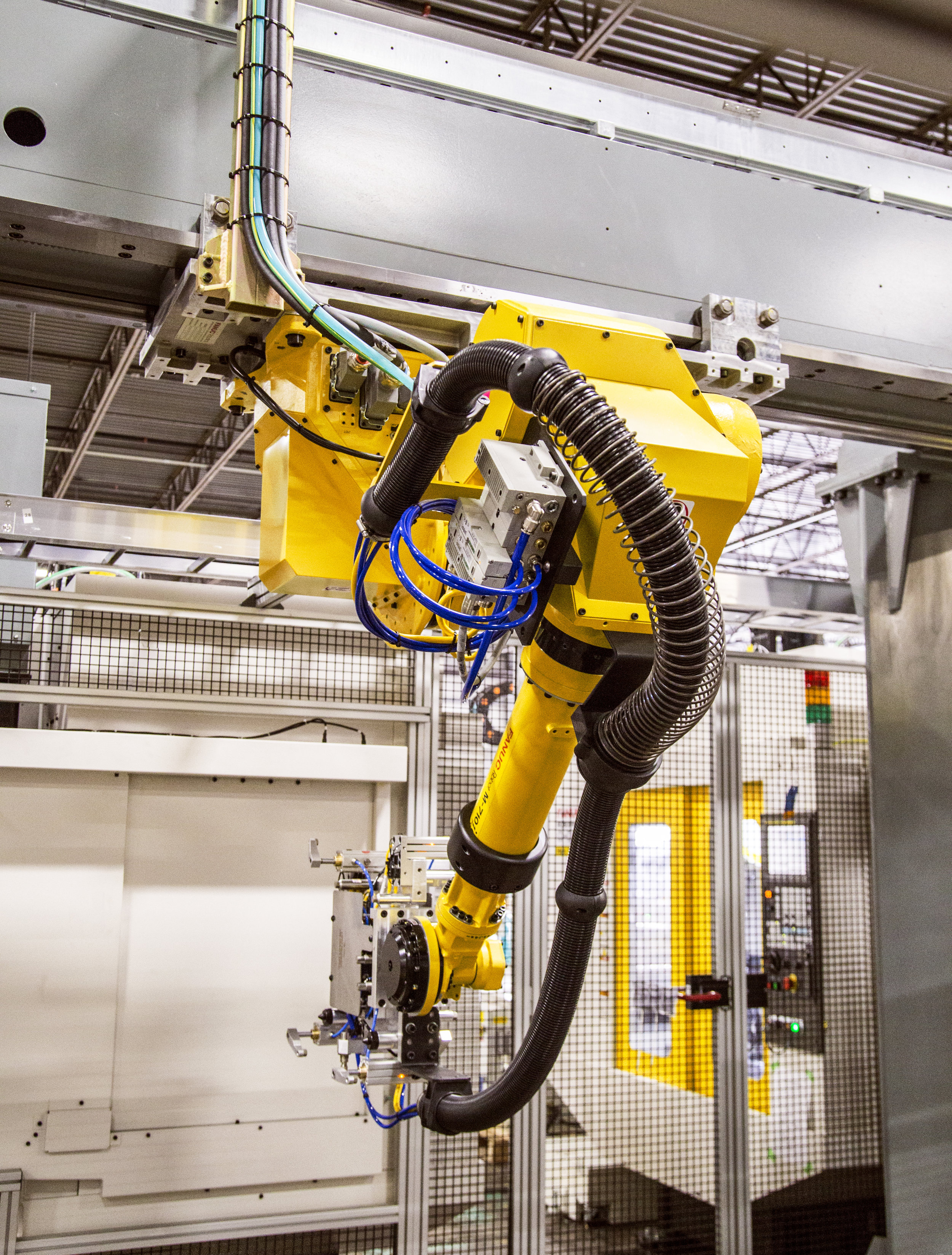

MACHINE LOAD / UNLOAD

Robotics significantly enhance machine tool load and unload operations by improving efficiency and productivity. Automated robotic systems enable faster cycle times while precisely handling various materials for consistent loading and unloading. These systems operate continuously, providing flexibility and reliability in production schedules. By integrating robotics, you optimize workflow and create a safer work environment, reducing physical strain on operators.

MATERIAL HANDLING

Robotics can greatly enhance your material handling applications by increasing efficiency, accuracy, and safety. Automated systems can transport, sort, and store goods, significantly reducing time and labor. By streamlining workflows and minimizing product damage, robotics enhance inventory management and seamlessly integrate with existing processes. These adaptable systems operate continuously and can flexibly meet changing demands, boosting productivity while creating a safer work environment by reducing workplace injuries.

ASSEMBLY

Robotics can greatly enhance your assembly applications by improving speed, precision, and consistency. Automated systems efficiently handle repetitive tasks, ensuring high-quality assembly with minimal errors. They offer flexibility to adapt to different products, making it easier to meet changing production demands. By integrating robotics into your assembly application, you can reduce cycle times, increase throughput, and allow human workers to focus on more complex tasks, all while fostering a safer work environment and driving overall productivity.

LASER MARKING

We specialize in engineering custom laser marking systems designed for your specific applications. Our advanced systems integrate with robotics to enhance efficiency and precision in the marking process. By automating laser marking, we streamline workflows, reduce cycle times, and ensure consistent quality. Robotics enables precise positioning and movement for complex marking patterns on various materials, increasing productivity while minimizing human intervention. Trust our expertise to provide innovative laser marking solutions that elevate your production capabilities.

MATERIAL REMOVAL and VISION SYSTEMS

Robotics greatly enhance material removal and polishing applications by providing consistent precision and efficiency. Automated systems handle tasks like grinding, sanding, and polishing uniformly, reducing labor costs and minimizing operator fatigue while ensuring a high-quality finish.

With integration of advanced sensors and vision systems, robotics improve accuracy and adapt to various shapes and sizes. This technology speeds up production, improves safety by taking over hazardous tasks, and boosts overall productivity in your operations.